Textile machinery selects Kinri's dustproof and vibration resistant power sources! More suitable, durable, and user-friendly in harsh operating environments!

The operating environment of textile machinery is harsh. In order to achieve large-scale production, production equipment must be efficient and reliable to meet the development needs of the industry. The power supply manufactured by Kinri effectively meets the requirements of harsh operating environments for textile machinery.

Kinri Swithcing Power Supply: dust-proof, moisture-proof, vibration resistant, and strong environmental adaptability

1. Dust proof, moisture-proof, and vibration resistant

From the perspective of application environment, textile production equipment has special application conditions and certain risk factors:

1) Fan: During the operation of the equipment, it is inevitable to produce a lot of cotton wool and dust from textiles. The fan will blow these objects into the interior of the power supply, causing a risk of short circuit; Moreover, cotton wool and dust can easily block the fan, causing the power supply to be unable to dissipate heat and heat damage.

2) Unprotected: If cotton wool and dust from textiles fall into the interior of the power supply, without protective measures, it is easy to cause a short circuit inside the power supply, causing damage, and even leading to internal cotton fires, resulting in a fire.

3) Product moisture: The shell with holes and the hollow structure inside the shell cannot block water vapor, and at the same time, the fan's air inlet becomes a channel for damp water vapor. When the sealing of the internal environment of the power supply is insufficient to block water vapor, encountering harsh indoor and outdoor environments, etc., will directly affect the service life of the power supply and equipment.

4) Strong vibration environment: Textile equipment usually uses processes such as vibration, pulling, and impact to achieve fiber separation and impurity removal, thus requiring high requirements for the anti vibration ability of the power supply.

Kinri's fanless semi adhesive power supply series adopts a fanless design to solve dust accumulation and meet 3G vibration testing requirements; The glue filling process prevents cotton wool and dust from falling into the interior of the power supply, while blocking water vapor, ensuring equipment reliability.

2. Strong environmental adaptability

The conventional input voltage range is 85-264VAC, but it cannot handle all situations, such as the instantaneous input voltage exceeding 264VAC when the equipment is started and turned off, which poses a risk of damage to conventional products; For example, during periods of high and low electricity consumption, voltage fluctuations can exceed 264VAC; For example, the equipment has a demand for export overseas and cannot meet the electricity standards overseas.

The Kinri fanless semi adhesive power supply LMF-UH series products have a wide input voltage range of 85-305VAC, fearless of power grid fluctuations; In addition, the operating temperature range of the product is -40 to+85 ℃, with a lower operating temperature, expanding the application area to meet lower environmental applications, fast start without restriction, specially designed for conduction and heat dissipation scenarios, and not reduced in a windless environment of 55 ℃.

At the same time, the LMF-UH series can maintain a peak power output of 1.5 times for 1 second, meeting the transient high current demand of motor startup and other advantages. It is widely used in strong vibration environments of knitting machinery, spinning machinery and other equipment, bringing customers better choices.

In addition, if there is a need for safety and salt spray prevention, the Kinri fanless semi adhesive power supply LMF-UH series has derivative series LMF-UH-C and LMF-UH-YW with input terminals with terminal covers and salt spray prevention, making it convenient for customers to choose according to their needs.

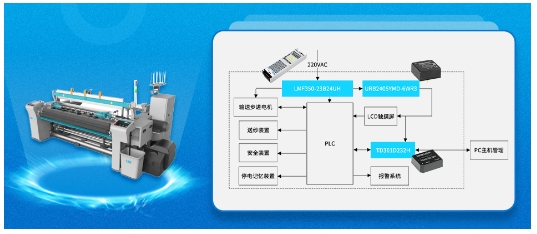

Typical application solutions in the textile industry

In the textile equipment system, the front-end power supply LMF350-23B24UH is connected to the mains input and outputs 24V to supply power to the back-end PLC, stepper motor and other components. The product can achieve 1.5 times the peak power for continuous output for 1 second, meeting the transient high current generated by the back-end motor startup; Connect URB2405YMD-6WR3 to the backend and reduce the voltage to 5V to power the LCD touch screen.

The power supply of textile machinery needs to have three protections and meet certain vibration level requirements; The accumulation of cotton wool inside the equipment can easily lead to power failure. Kinri's LMF-UH series not only meets the above requirements and ensures high reliability, but also takes into account the advantages of domestic brands, complete protection functions, fast delivery, and localized fast services, bringing customers better choices.

Summary

With the improvement of intelligence in the textile industry, the performance and safety requirements of textile equipment are also increasing, and the requirements for power supply solutions are becoming more and more refined and diverse. Kinri has a rich product line that can be applied to different scenarios, meet various needs, and has a strong R&D team and technical support team to provide one-stop power solutions.